Welding, brazing and soldering are the methods of joining two or more pieces of metal and others materials. They are also used to fill gaps in metal parts. Each types of joining process has its own significance. Metal joining process to be applied for joining two parts depends on many factors. Below see the comparison of welding, brazing and soldering in aspects like strength, temperature requirement, change in properties, cost involvement, heat treatment etc.

Welding:

- A process of joining two similar or dissimilar metals by fusion.

- Without or with the application of pressure.

- Without or with the use of filler materials

- It is the most strongest joints used to bear the load. Strength of the welded portion of joint is usually more than the strength of base metal.

- The temperature requirement is 3800°C in welding joints

- To join work pieces it is need to be heated till their melting point.

- Mechanical Properties of the base metal may be change at the joint due to heating and cooling.

- Heat treatment is generally required to eliminate the undesirable effects of welding.

- No preheating of workpieces is required before welding as it is carried out at high temperature.

Soldering:

- A process of joining two or more parts together by molten metal.

- It uses a different metals with a low melting point to join the two parts/ items.

- It is a quick method of making joint.

- Soldering joints are the weakest joints out of three. Not meant to bear the load

- It is used to make electrical contacts generally.

- It needs a temperature requirement of up to 450°C

- Heating of the workpiece may not be required.

- No change in mechanical properties after joining.

- No heat treatment is required.

- Preheating of metals/workpieces before soldering is good for making good quality joint.

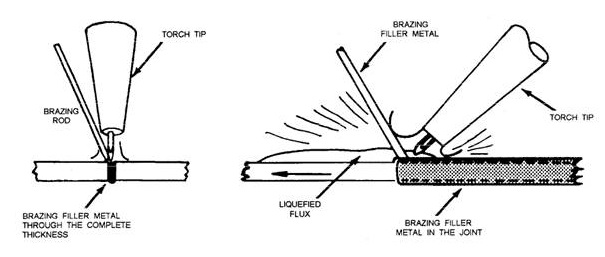

Brazing:

- Brazing is a soldering operation using brass as the joining medium.

- It is the weaker joint than welding joints but stronger than soldering joints. This can be used to bear the load upto some extent.

- Temperature requirement may go to 600°C in brazing joints.

- Work pieces may be heated but below their melting point.

- May change in mechanical properties of joints but it is almost negligible.

- No heat treatment is required after brazing.

- Preheating is desirable to make strong joint as brazing is carried out at relatively low temperature.

No comments:

Post a Comment